Dacheng seismic isolators are categorized into two basic designs : Lead rubber bearing and High damping rubber bearing.

- Lead Rubber Bearing

Brief Introduction : Lead Rubber Bearing is an isolation system which combines laminated layers rubber bearing with lead plugs; the former bears the load and isolates vibration, and the latter absorbs energy as a damper.

Brief Introduction : Lead Rubber Bearing is an isolation system which combines laminated layers rubber bearing with lead plugs; the former bears the load and isolates vibration, and the latter absorbs energy as a damper.

Application : Lead rubber bearing find wide applications in structures, such as Civil constructions, Hospitals, The museum, Schools etc.

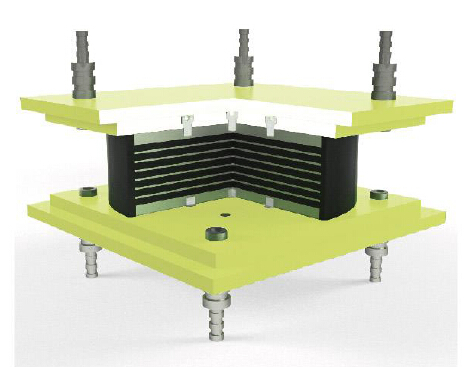

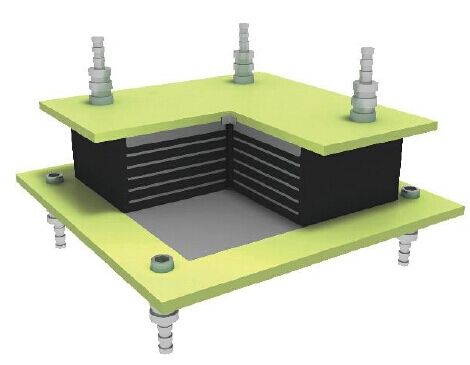

Introduction : Lead rubber bearing is an isolation system which combines laminated rubber layers, steel reinforcing plates and lead plugs. The lead plug absorbs energy as a damper; the steel plates can improve the vertical stiffness of the bearing to support the upper structures and building structures of the bridge efficiently; the rubber layers give the bridge the function of high elastic deformation, but also has larger damping, big horizontal displacement ability and resetting function. It is an isolation device that combiness support and energy consumption.

Introduction : Lead rubber bearing is an isolation system which combines laminated rubber layers, steel reinforcing plates and lead plugs. The lead plug absorbs energy as a damper; the steel plates can improve the vertical stiffness of the bearing to support the upper structures and building structures of the bridge efficiently; the rubber layers give the bridge the function of high elastic deformation, but also has larger damping, big horizontal displacement ability and resetting function. It is an isolation device that combiness support and energy consumption.

Size Range : Lead Rubber Bearing from 400mm *400mm to 1750mm*1750mm with capacities of up to 4,000 tons are manufactured. Custom dimensions are available for special applications.

- High Damping Rubber Bearing For Bridge and Building

High damping rubber bearing HDR is made of a rubber compound with high natural rubber (NR) content and has been specially designed to combine friction damping and viscous damping. As a result, it offers excellent functionality as a seismic isolation bearing, providing restorative attributes of rubber springs along with superior damping performance and high-level durability.

NO.1 : The HDR bearing is installed on bridge pier and beam with sleeves and anchoring ord,the embedded steel plates are installed on the top and bottom of bearing, the sleeves are fixed on the top steel plate and bottom steel plate of the bearing by assembling bolt, the top and bottom embedded steel plates are designed to be welded installing with sleeves.

No.2 : The HDR bearing is instaled on the bridge pier and bearn with sleeves and anchoring rod. The embedded steel plates are installed on the top of bearing but the bottom of the bearing have no embedded steel plates installed. The sleeves are fixed on the bottom seal layer steel plate by assembling bolt. The top embedded steel plate is installed on the top seal layer steel plate by shearing force cogged. The top embedded steel plates are designed to be welded installing with sleeves.

NO.3 : The realize of the sliding HDR bearing dispalcement is through the sliding friction of the ptfe plate and the corrosion resistant plate that on the top of the HDR bearing.Low friction coefficient made the HDR bearing load low friction. By sliding friction sliding to realize the functions of vibration isolation.

NO.3 : The realize of the sliding HDR bearing dispalcement is through the sliding friction of the ptfe plate and the corrosion resistant plate that on the top of the HDR bearing.Low friction coefficient made the HDR bearing load low friction. By sliding friction sliding to realize the functions of vibration isolation.

Customer Support : Our product specialists will be glad to advise you in selection of the optimal solution for your project, and to provide you with a quotation.