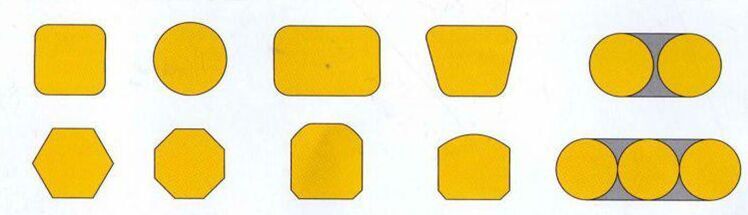

Rubber balloon for culvert formworks is a kind of cylinder bag that can expand, shrink, used to form concrete component of cavity. It is easy to be used, convenient and durable, is soft and can fold, curly, contraction when it isn’t inflate, it have the enough strength to withstand the pressure of concrete when it is inflated, this is incomparable with any traditional template, it is used in reinforced concrete members, including stake roof, roof board column, beam, building, water conservancy project(shipyards slipway, dock) . Construction practice proves that inflatable rubber mandrel is simple, not only save materials. And has a shape characteristics, it could be round. Oval, rectangle, vaulted, trapezoidal pipeline. etc. Also you can make a straight hole, etc. can make a building structure light ,thin wall hollow .change the concrete performance have been used rigid characteristic template situation,

The Performance characteristic:

1、Design scientific and reasonable used inflatable rubber mandrel, or casting parts, finished product can meet the requirement of design, easy operation, save time, save material.Have good ageing resistance performance and long service life this product use synthetic rubber ,natural rubber and strengthen layer vulcanize, Has very good resistance to bulge, flexibility and elasticity so can satisfy all sorts of work in the conditions of use.

2、Widely applicable temperature, within the scope -10℃-+90℃ of the material without change .

3、For building light-duty construction provides favorable conditions to stress hollow concrete. Component, due to the rubber mandrel ,the weight than use stress solid component light 20%,so it can reducing the weight of the upper structure of building .can make the pipe foundation short. increase span, make the construction become simple and safety.

4、Construction technology is simple ,safe, health, use it only need a few simple tools, without special process. Only put the mandrel into negative reinforcement cage, inflate air to achieve work pressure ,then pouring the concrete. When the concrete freezing ,put gas our mandrel., in thus complete the product component forming. and it not pollute the environment.